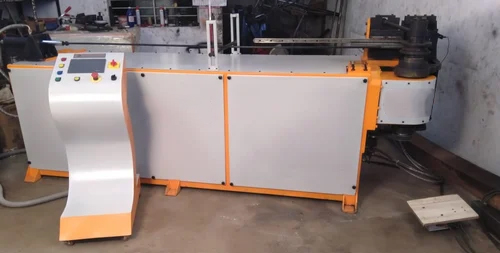

NC Bending

Conventional bending of single or multiple bends by draw bend process on semi-automatic machines.

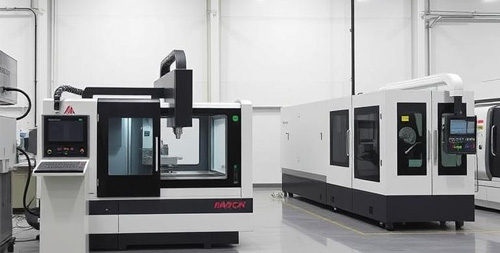

CNC Bending

Multiple, multiplane bends by drawbend process on fully automatic CNC machines.

Roll Bending

Bending by 3 roll method is generally employed for generation of multiple/variable radii for heat exchanger tubes and for large radius/semi elliptical forms.

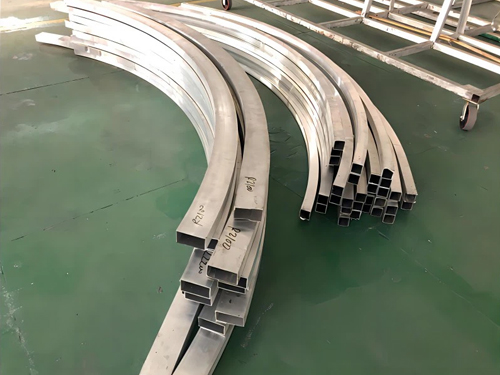

Stretch/Form Bending

Products, generally aluminum extrusions and rolled steel sections are stretch formed or form bent using special tooling. Examples include automotive bumpers, door frames, fenders in steel; facade components, automotive/marine windows etc in aluminum.

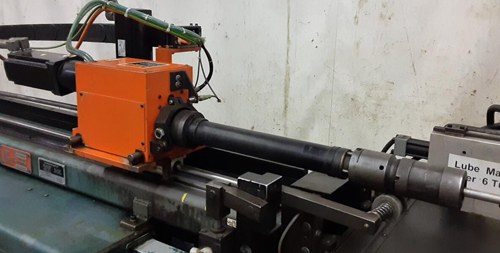

Boost Bending

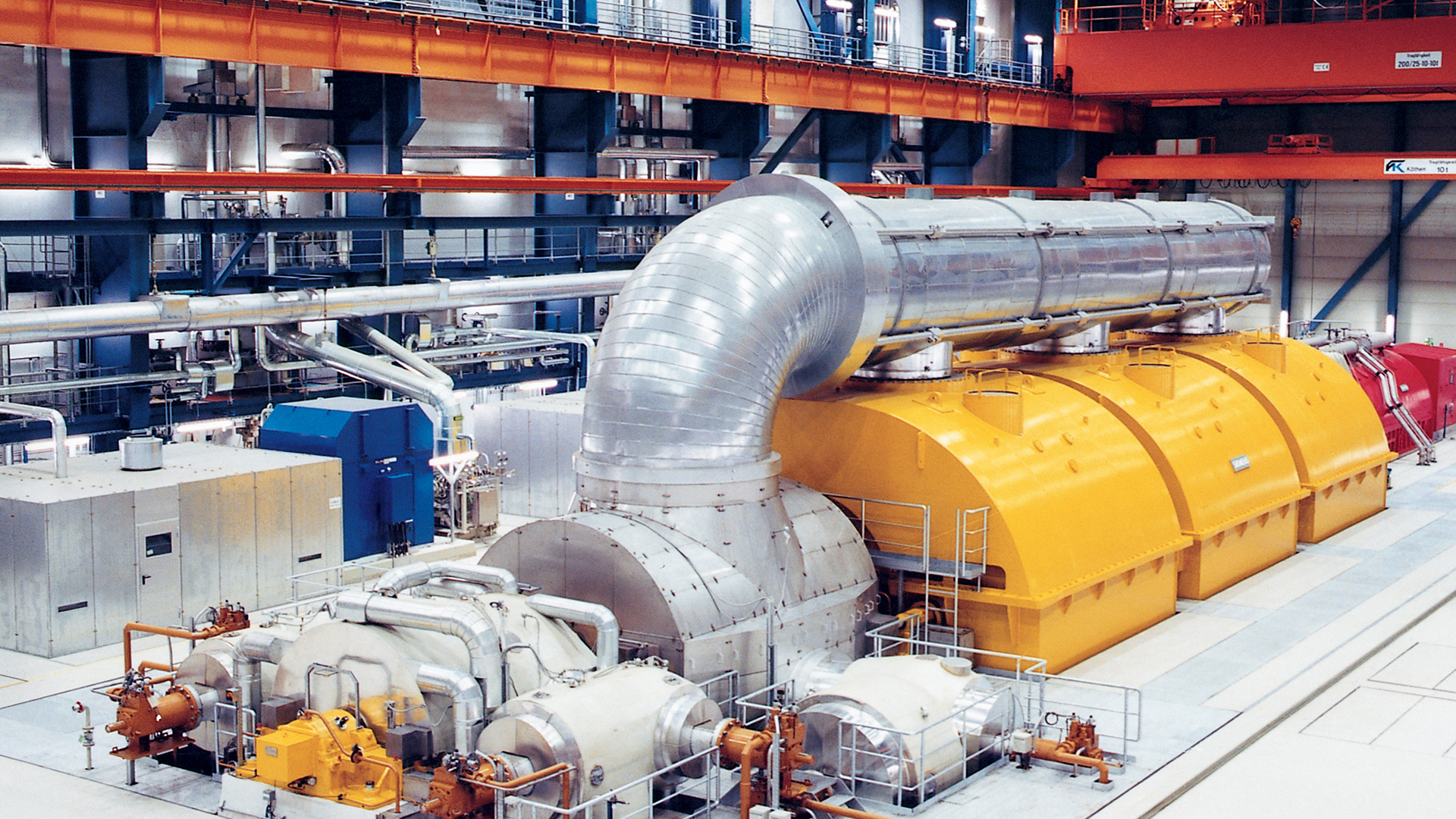

Draw bending with 'Clamp & Boost' process is employed for ovality / thinning controlled bends on tight radius(R ≥D), for boiler & Power generation equipments.

Squeeze Bending

Generally thick walled pressure parts of applications like boiler, coal gassifier, and piping for constraint zones are squeeze bent in hot condition.

Push Bending

Large radius bends for boiler, heat exchanger & chemical plants are generated to the desired radius without use of a bending die. Even small batch production of up to 8" is available.

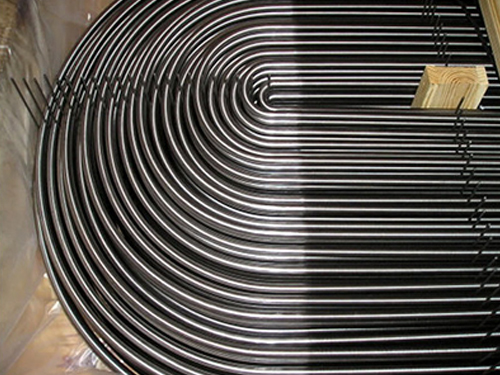

Coiling

Different types of coils-serpentines helical, double step, conical helix, oddpitch helix, spiral etc are handled using different process of 3 roll bending, draw bending, and dedicated form bending.

Tube Fabrication Assembly

Different types of coils-serpentines helical, double step, conical helix, oddpitch helix, spiral etc are handled using different process of 3 roll bending, draw bending, and dedicated form bending.

End Forming | Swaging

End Forming of different forms – expansion, reduction, necking, single/double flaring, spherical forming, single/double beading, cone forming, punching, perforation, notching, slitting, flattening, curling & size calibration are handled with utmost precision.

Module Assembly

module assembly involves constructing a building or structure by assembling prefabricated steel components, typically in a factory setting and then transporting and erecting them on site.

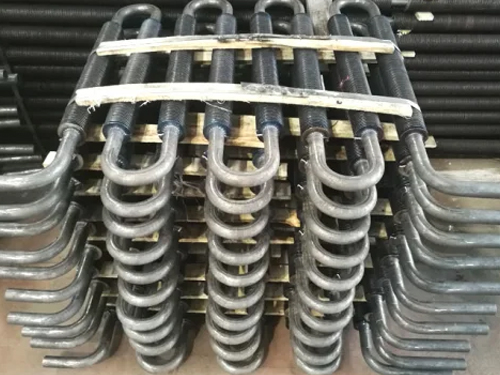

Finned Tube Bending

Finned tube bending involves shaping tubes with fins, typically in a U-bend configuration, to enhance heat transfer efficiency. These bends are commonly used in heat exchangers and other industrial applications. The U-shape and fins increase surface area, allowing for better heat dissipation or absorption.

Heat Treatment | Hydrotest

A hydrotest, or hydrostatic test, is a pressure test that uses water to check the integrity of a system, such as a heat exchanger, pipeline, or pressure vessel. It's a way to ensure that a system can withstand the pressure it will be subjected to during operation and that it doesn't have any leaks.

RT Compliant Welding | Testing

Radiographic Testing (RT) is a Non-Destructive Testing (NDT) method used to inspect welds for defects by using penetrating radiation like X-rays or gamma rays. A film is used to capture an image of the internal structure of the weld, revealing flaws like cracks, porosity, or incomplete fusion. RT is a common method in various industries, especially in construction and manufacturing

Bollard

A bollard is a sturdy, short, vertical post. The term originally referred to a post on a ship or quay used principally for mooring boats. In modern usage, it also refers to posts installed to control road traffic and posts designed to prevent automotive vehicles from colliding with pedestrians and structures.