Alloy 825 / UNS No. N08825 / EN 2.4858

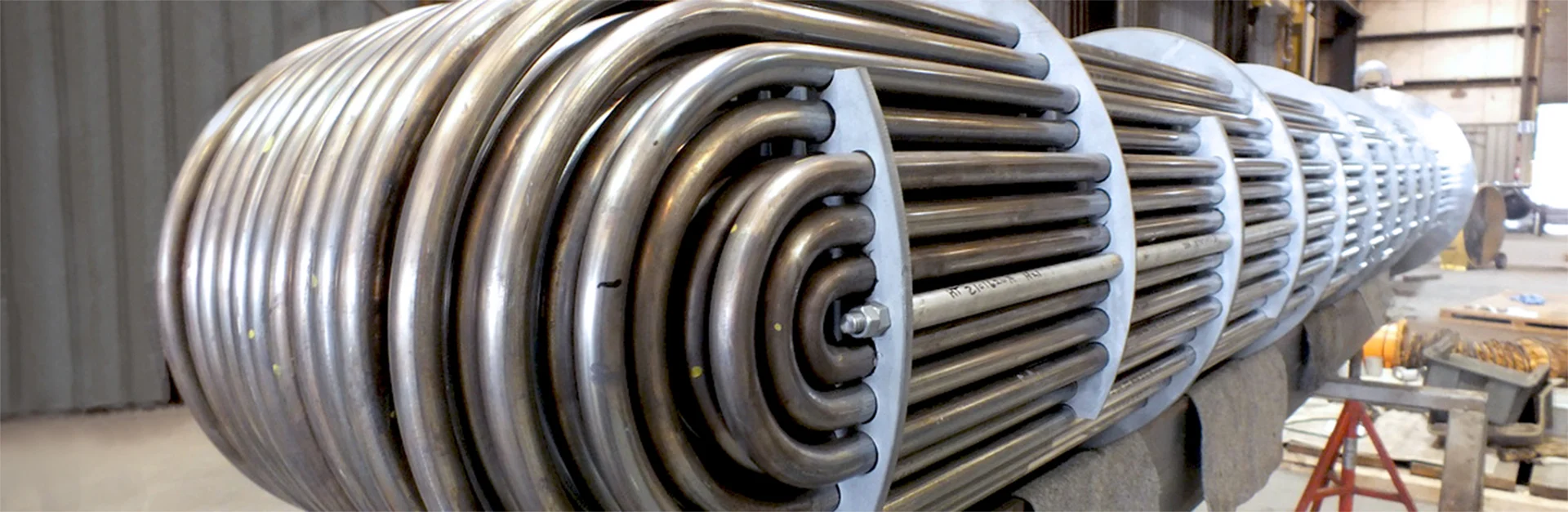

Shashwat Stainless Inc is a leading manufacturer and exporter of Incoloy 825 Tubes, renowned for their exceptional durability and versatility in demanding environments. Crafted to meet international quality standards, these tubes offer outstanding resistance to corrosion, making them ideal for industries such as chemical processing, aerospace, and marine applications. With superior performance in both oxidizing and reducing conditions, Incoloy 825 Tubes excel in resisting acids, pitting, and stress-corrosion cracking, ensuring reliable operation in extreme conditions.

Engineered for high-temperature performance, these tubes are the perfect solution for applications requiring strength and stability under thermal stress. Their robust design and adaptability make them a preferred choice for a wide range of critical industrial processes.

Explore the unmatched quality and reliability of Incoloy 825 Tubes by Shashwat Stainless Inc. Contact us today to learn more about our products or to request a custom quote tailored to your project’s needs.

Premium Quality Steel Tubes Manufacturer & Exporters in India.

Alloy 825 / UNS No. N08825 / EN 2.4858 Specifications

| Types | Seamless & Welded |

|---|---|

| Form | Round |

| Outside Diameter | 12.70 mm to 50.80 mm |

| Wall Thickness | 0.89 mm to 5.00 mm |

| Length | Up to 30mtr long |

| Standard/Specification | ASTM, ASME, ISO, EN, NORSOK, JIS, NACE, DIN, AFNOR |

Alloy 825 / UNS No. N08825 / EN 2.4858 Chemical Composition (%)

| Elements | Nickel | Chromium | Iron | Manganese | Carbon | Copper | Silicon | Sulfur | Aluminum | Titanium | Molybdenum |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | 38.0–46.0 | 19.5–23.5 | 22.0 min | 1.0 max | 0.05 max | 1.5–3.0 | 0.5 max | 0.03 max | 0.2 max | 0.6–1.2 | 2.5–3.5 |

Application of Alloy 825 / UNS No. N08825 / EN 2.4858

- Pulp & Paper Industries

- Ship Industries

- Aerospace Industries

- Refineries Industries

- Power Plant Industries

- Oil & Gas Industries

- Sugar Industries