309S / UNS No. S30908 / EN 1.4833

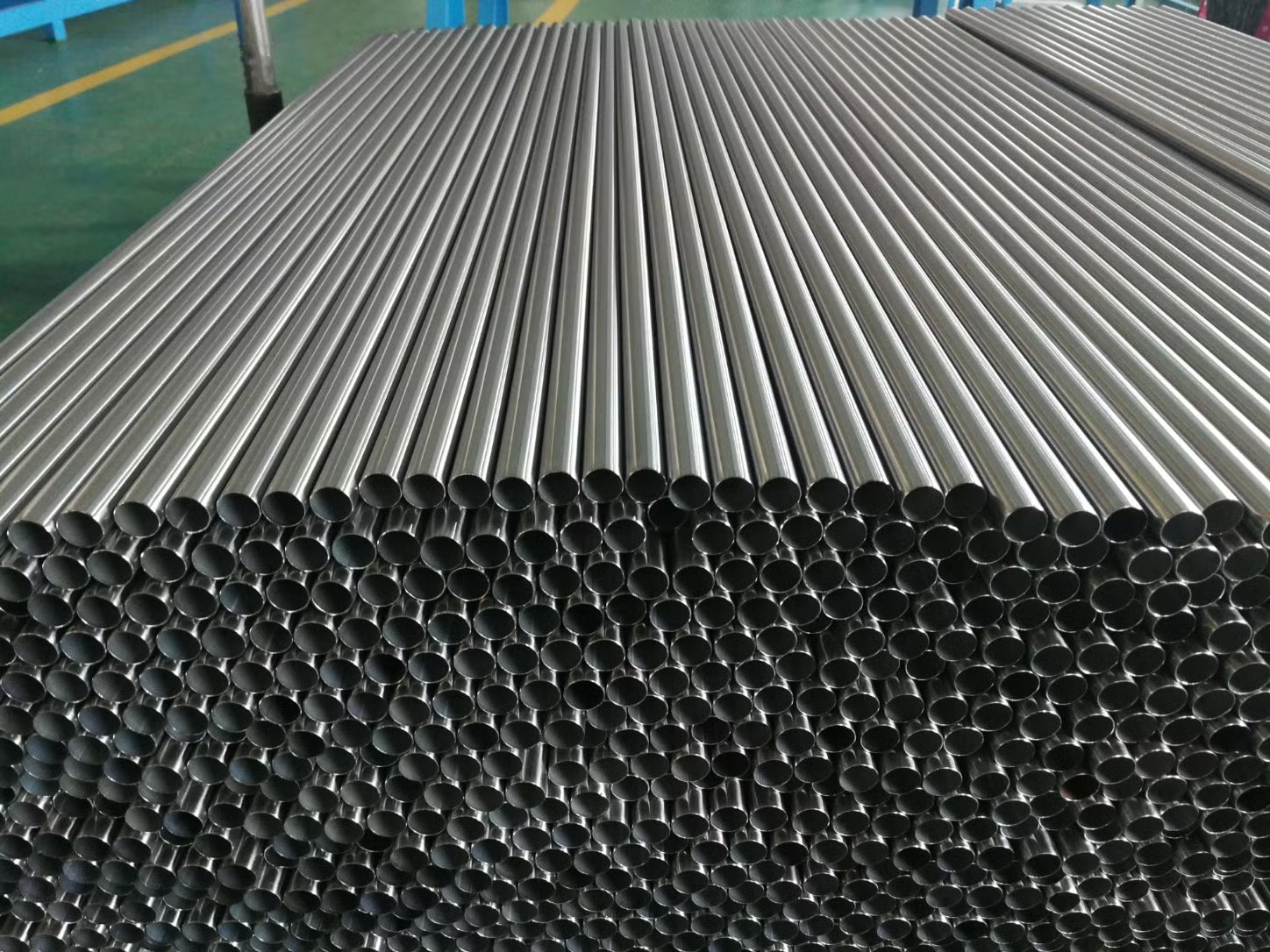

Shashwat Stainless Inc, a leading Stainless Steel 309S Tubes manufacturer and exporter, delivers high-performance solutions engineered for extreme environments. Crafted to meet international standards, these tubes offer exceptional corrosion resistance and outstanding durability, even under high-temperature conditions. Their ability to withstand both oxidizing and reducing atmospheres makes them ideal for critical applications in industries like chemical processing, aerospace, and marine engineering.

Renowned for their versatility, Stainless Steel 309S Tubes excel in demanding environments, providing reliable performance in heat-intensive and corrosive settings. Their superior strength and resilience ensure long service life, reducing maintenance costs and downtime.

Whether you're tackling extreme temperatures or corrosive substances, trust Shashwat Stainless Inc for top-quality solutions tailored to your needs. Explore the full range of Stainless Steel 309S Tubes or contact Shashwat Stainless Inc today for expert guidance and competitive quotes.

Premium Quality Steel Tubes Manufacturer & Exporters in India.

309S / UNS No. S30908 / EN 1.4833 Tubes Specifications

| Types | Seamless & Welded |

|---|---|

| Form | Round, Square, Rectangle, Coil, "U" Tubes, Hydraulic & Honed Tubes |

| Size | 1/4" OD TO 12" OD. GAUGE: 25 SWG-10 SWG |

| Standard/Specification | ASTM, ASME, ISO, EN, NORSOK, JIS, NACE, DIN, AFNOR |

309S / UNS No. S30908 / EN 1.4833 Chemical Composition (%)

| Elements | Carbon (C) | Manganese (M) | Phosphorus (P) | Sulfur (S) | Silicon (SI) | Chromium (CR) | Nickel (NI) | Molybdenum (MO) | Nitrogen (N) | Copper (CR) | Other Elements |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | 0.08 | 2.00 | 0.045 | 0.030 | 0.75 | 22.0–24.0 | 12.0–15.0 | - | - | - | - |

Application of 309S / UNS No. S30908 / EN 1.4833

- Pulp & Paper Industries

- Ship Industries

- Aerospace Industries

- Refineries Industries

- Power Plant Industries

- Oil & Gas Industries

- Sugar Industries